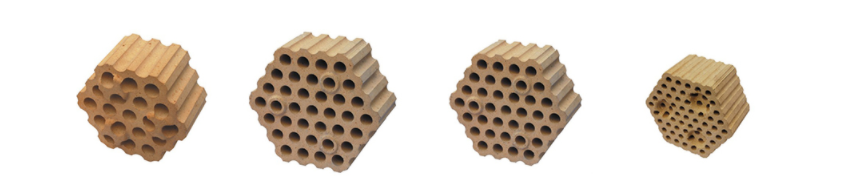

Refractory checker bricks are currently widely recognized and accepted by the world's ironmaking industry. They have strong heat exchange capacity, large heat storage area, smooth ventilation, low resistance and many other excellent types of checker bricks. Heat storage body. Checker brick is a kind of heat transfer medium, which is used in the blast furnace hot blast stove regenerator. It is usually arranged in an orderly manner in the regenerator. It has the function of storing heat during the "burning period" and during the "air supply period". Through convective heat exchange and radiant heat exchange, the cold air is heated into hot air.

At present, refractory checker bricks are mainly used in blast furnace hot blast stoves and flame stoves. Refractory checker bricks are mainly used in the regenerator of hot blast stoves. Checker bricks with lattice holes are arranged in an orderly manner. The upper and lower through holes of the checker bricks can allow gas to pass through. According to the technical requirements of different temperature areas, siliceous checker bricks, clay bricks, etc. are generally used. In some hot blast stoves, high alumina bricks, mullite bricks, sillimanite bricks, etc. are also selected.

The function of the hot air stove is to heat the cold air sent by the blower to the blast furnace into hot air, and then the hot air is sent to the blast furnace through the hot air pipe for combustion reaction. The blast furnace hot blast stove has a furnace burning period and an air supply period, and the two working periods are cycled. In the furnace burning period, the high-temperature flue gas after combustion passes through the holes of the checker bricks of the hot blast stove to transfer heat to the checker bricks; during the air supply period, the cold air from the blower enters the hot blast stove and is heated by the checker bricks into hot air. It is sent to the blast furnace through the hot air pipe.

Fireclay bricks for hot blast stoves are one of the main varieties of silica-alumina series products. They are refractory products with 30-48% Al2O3 content made of fireclay clinker as aggregate and refractory clay as binder. The refractoriness of high-quality fireclay bricks is comparable to that of silica bricks, up to 1690~1730℃, but the softening temperature under load is more than 200℃ lower than that of silica bricks.