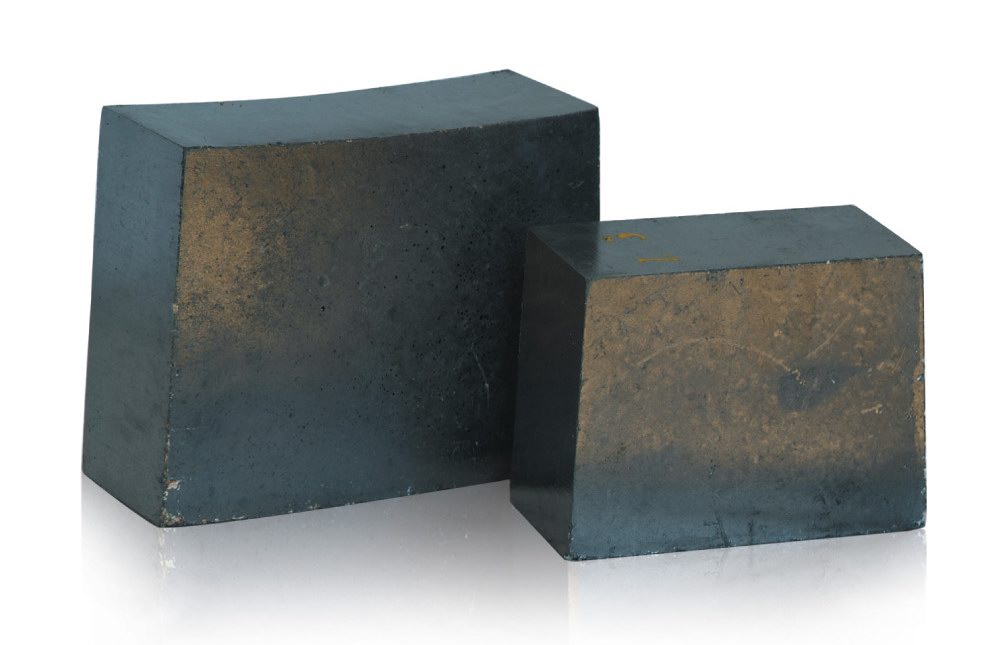

Alumina magnesia carbon brick is on Al2O3 substrates of carbon refractories, to high-quality bauxite clinker, adding an appropriate amount of electric melting brick magnesite,flake graphite and bonded by extrusion molding, low temperature roasting made.

Al2o3-mgo-c bricks containing Al2O360% ~ 69%, MgO7% ~ 14%, C5% ~ 12%. It has good resistance to slag corrosion and thermal shock resistance, there is a trace of re burning expansion. In order to improve the oxidation resistance, the Si powder, Al powder, SiC powder, silicon iron powder and other additives can be added in the ingredients, and the resin is a bond, and the resin is formed by high pressure, and can be used after being processed by 300 to 200 degrees

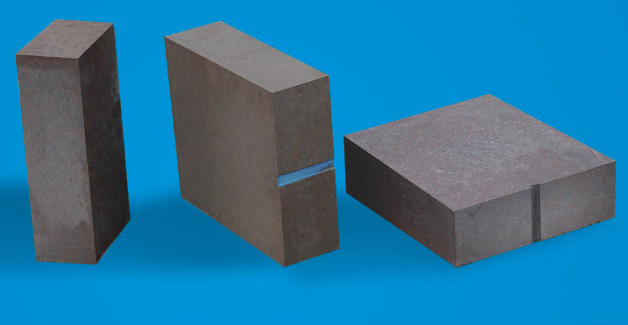

Features:

1. Alumina magnesite carbon brick with slag resistance and good thermal shock resistance.

2. Alumina magnesite carbon brick has a trace of reheating expansion.

3. Alumina magnesite carbon brick with high temperature stability and high temperature.

4. Alumina magnesite carbon brick with high slag corrosion, no shrinkage, no crack, no peeling, resistance to erosion, no sticky residue, no pollution to liquid steel etc..

5. Alumina magnesite carbon brick can greatly improve the oxidation resistance and the use cycle of al2o3-mgo-c bricks.

Applications:

Alumina magnesia carbon brick is mainly used for steel ladle lining brick and spout brick, also used in large converter and ultra high power electric furnace ladle lining and furnace refining furnace lining .