Argon blowing is usually to build one or several Porous Plug bricks at the bottom of the pouring ladle or brick ladle. After tapping, blow argon gas through the Porous Plug bricks to cause agitation of the molten steel in the ladle. Argon blowing can promote the floating of emulsified slag droplets and inclusions in steel, and can partially remove the dissolved gas and uniform components in the steel. In the case of continuous casting, the ladle blowing of argon can play a role in adjusting the temperature of the molten steel. Ladle argon blowing is an important steelmaking process, and Porous Plug bricks are an important functional element of this process.

Type and structure of Porous Plug brick

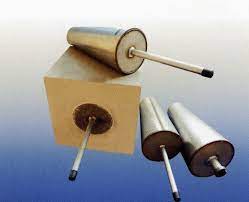

According to the gas channel form, there are three main types of air-permeable bricks, namely, the diffuse type, the straight-through directional type, and the slit-oriented type. The diffuse structure has fine pores, high porosity, low density and strength, and poor durability; the straight-through directional type is made of unequal numbers of thin steel pipes embedded in bricks, and there are also special pore-forming technologies without the orientation of thin steel pipes. The pore size is generally between 0.6mm and 1.0mm. The flow and distribution of gas in the direct-through ventilating brick are reasonable, the bottom blowing effect is good, and the service life is long, but it is easy to block in the later stage, which affects the blowing rate; slits The directional air-permeable brick is integrally formed with the inlay material during the forming process. During the high-temperature firing process, the inlay material is heated to melt and volatilize to form a slit, and the gas enters the ladle molten pool through the slit. Proper slit width can ensure low argon blowing intensity, control and adjust the flow rate, and avoid the danger of permeation and blockage. The slit width of the LF-VD refining ladle Porous Plug brick at Maanshan Iron and Steel No. 1 Steel Rolling Plant is selected to be about 0.18mm, and the Porous Plug brick can better meet the requirements of refining production.

According to the installation method, there are integral ventilating bricks and exterior ventilating bricks. The integral air-permeable brick has high safety factor, long service life and convenient installation; but it is difficult to replace. The integral ventilating brick is suitable for the process conditions that the argon blowing time is low and the life of the ventilating brick can be synchronized with the life of the ladle. The exterior air-permeable bricks are easy to replace, but because of the installation equipment, the structure is relatively complicated, and the quality requirements for the on-site installation of the brick cores are high, which is likely to cause man-made operation accidents. Because the externally mounted ventilating brick can quickly replace the brick core, it is beneficial to the turnover of the ladle and the improvement of the age of the ladle. It is suitable for the process conditions where the argon blowing time is long and the ventilating brick is frequently replaced, especially the refined ladle. At present, the slit directional air-permeable bricks are widely used on ladle.