Compared with other flat glass melting furnaces, the float glass melting furnace is not much different in structure. It is a shallow pool horizontal flame pool kiln, but in terms of scale, the float glass melting furnace is much larger in scale. The daily melting capacity of the float glass furnace can reach more than 1100t (usually expressed by 1000t/d). Although float glass furnaces are different from other flat glass furnaces, their structures have something in common. The structure of float glass melting furnace mainly includes: feeding system, melting system, heat source supply system, waste gas waste heat utilization system, exhaust gas supply system, etc.

One, feeding pool

The feeding pond, located at the beginning of the melting furnace, is a rectangular pond protruding from the outside of the kiln. The feeding port includes two parts: the feeding pond and the upper retaining wall (front face wall). The matching materials are put into the kiln from the feeding port.

1. The size of the feeding tank

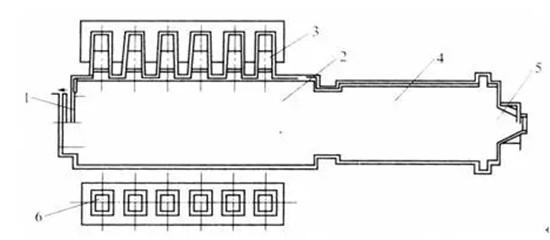

1- Feeding port; 2- Melting part; 3 - small furnace; 4- Cooling part; 5- Flow port; 6 - regenerator

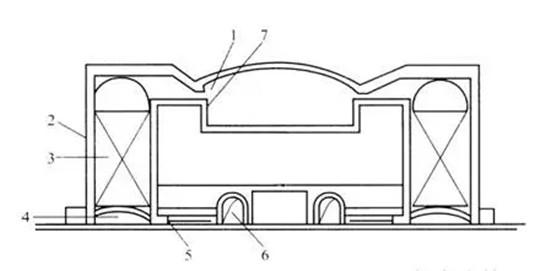

1- Small furnace mouth; 2- Regenerator; 3- Lattice; 4- Bottom flue; 5- Connect the flue; 6- A flue; 7- Fuel nozzle

Feeding is one of the important technological links in the melting process. It is related to the melting speed of the batch material, the hot spot position in the melting zone, and the stability of the bubble limit, which will affect the quality and output of the product. Since the melting amount of the float glass melting furnace is relatively large, a transverse flame pool kiln is adopted, and the feeding pool is set at the front end of the melting pool. The size of the feeding tank varies with the size of the melting tank, the batch material state, the feeding method and the number of feeding machines. The state of the batch materials is powder, granule and slurry (currently powder is generally used); the feeding method is determined by the selected feeding machine, and there are spiral, ridge, roller, reciprocating, wrap-in, electromagnetic vibration Style and slanted blanket style etc. (Currently, ridge feeder and inclined blanket feeder are mostly used).

(1) The size of the feed tank using the ridge feeder depends on the number of feeders selected. The length of the feed tank can be determined according to the process layout and the structural requirements of the front face wall.

(2) The size of the feeding pool using the inclined blanket type feeder The inclined blanket type feeder has reached universal use in the market. Its feeding method is similar to the ridge type feeder, except that the feeding surface is wider than the ridge type feeder. There are many, so the size of the feeding pool is not much different from the size of the feeding pool using the ridge feeder, and it is still determined by the width of the melting pool and the requirements of the feeding surface.

With the maturity of glass melting technology and the renewal of melting process, the width of float glass melting furnace feeding pool is getting larger and larger. Because the amount of heat absorbed by the batch material is proportional to its coverage area, the wider the feeding tank, the larger the coverage area of the batch material, the more conducive to improving thermal efficiency and energy saving, and to improving the melting rate. Therefore, at present, in the design of large-scale float glass melting furnaces, the feeding tank and the melting tank are of equal width and quasi-equal width models. With the continuous increase of the width of the feeding tank, large-scale inclined blanket feeder also came into being. The melting furnace and the melting tank with a width of 11m are both used. Two inclined blanket feeders can meet the production and technical requirements.